Customized Solutions for Challenging Applications

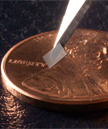

Delaware Diamond Knives fabricates single crystal diamond parts from all types of diamond, all crystallographic orientations, and a wide range of dimensions and geometries. Single crystal diamond offers outstanding properties for the most challenging applications. Delaware Diamond Knives produces unique windows, targets, diamond slabs, and other parts customized to fit our client’s requirements. We produce single crystal diamond plates as thin as 20um in all orientations, <100>, <110>, <111>.

DIAMOND WINDOWS

Diamond is highly transparent over a wide range of wavelengths , including x-ray, visible, IR, microwave, terahertz and more. Decades ago, diamond’s transparency, mechanical strength, resistance to scratching and chemical and biological inertness made it the material of choice for windows on a spacecraft to Venus. Today, these same properties make diamond an increasingly popular choice for windows in harsh or sensitive applications here on earth. Below are examples of window applications where the properties of diamond has proven to be highly effective.

Diamond is highly transparent over a wide range of wavelengths , including x-ray, visible, IR, microwave, terahertz and more. Decades ago, diamond’s transparency, mechanical strength, resistance to scratching and chemical and biological inertness made it the material of choice for windows on a spacecraft to Venus. Today, these same properties make diamond an increasingly popular choice for windows in harsh or sensitive applications here on earth. Below are examples of window applications where the properties of diamond has proven to be highly effective.

Flow Cells

Diamond is used as windows in flow chamber accessories for IR spectrometers. Its biological inertness makes it an ideal substrate for cell growth studies. A relatively constant index of refraction makes for minimal dispersion and superior transmission across the mid- IR and visual spectral wavelengths allowing for chemical imaging of living cells. Its chemical inertness makes the diamond easily cleaned between studies, too. The flow chamber made with sub micrometer thick diamond allows for a slim profile which minimizes working distances.

Diamond is used as windows in flow chamber accessories for IR spectrometers. Its biological inertness makes it an ideal substrate for cell growth studies. A relatively constant index of refraction makes for minimal dispersion and superior transmission across the mid- IR and visual spectral wavelengths allowing for chemical imaging of living cells. Its chemical inertness makes the diamond easily cleaned between studies, too. The flow chamber made with sub micrometer thick diamond allows for a slim profile which minimizes working distances.

Failure Analysis

Thin diamond windows are finding applications in semiconductor failure analysis. Tougher and more durable than sapphire, diamond is preferred in sensitive magnetic microscopes that probe fields in operating ICs. IREM – InfraRed Emission Microscopy – also utilizes diamond as an interface between an operating IC and the infrared detector. Diamond’s unsurpassed thermal conductivity together with its exceptional IR transmission help in the detection of hot spots during IC development and troubleshooting. The superior strength of diamond allows for relatively thin window dimensions minimizing both cost and absorption.

Thin diamond windows are finding applications in semiconductor failure analysis. Tougher and more durable than sapphire, diamond is preferred in sensitive magnetic microscopes that probe fields in operating ICs. IREM – InfraRed Emission Microscopy – also utilizes diamond as an interface between an operating IC and the infrared detector. Diamond’s unsurpassed thermal conductivity together with its exceptional IR transmission help in the detection of hot spots during IC development and troubleshooting. The superior strength of diamond allows for relatively thin window dimensions minimizing both cost and absorption.

Spectroscopy

Diamond is widely used as the sample surface in FTIR accessories. Its mechanical strength permits significant forces to be used insuring intimate contact with the sample. Low absorbance gives great throughput improving the instrument’s sensitivity across a broad spectral band. Diamond’s chemical and abrasion resistance makes it impervious to thorough cleaning and especially valuable in situations with abrasive and/or corrosive chemicals are analyzed.

Diamond is widely used as the sample surface in FTIR accessories. Its mechanical strength permits significant forces to be used insuring intimate contact with the sample. Low absorbance gives great throughput improving the instrument’s sensitivity across a broad spectral band. Diamond’s chemical and abrasion resistance makes it impervious to thorough cleaning and especially valuable in situations with abrasive and/or corrosive chemicals are analyzed.

BEAM LINE COMPONENTS

The unsurpassed thermal conductivity of diamond and its low absorbance makes it an ideal material for beamline components, especially as the power of these x-ray, laser and reactive ion beamlines continue to increase. Whether your beam is photons, protons or heavier ions, diamond will minimize beam losses and efficiently conduct energy that is lost to the cooling systems. Diamond is increasingly used for output coupling, filtering, beamsplitting, beam detection, position monitoring and sample holding. Diamond is often brazed into flanges to withstand pressure differences and can be thin enough to minimize absorption of x-rays.

The unsurpassed thermal conductivity of diamond and its low absorbance makes it an ideal material for beamline components, especially as the power of these x-ray, laser and reactive ion beamlines continue to increase. Whether your beam is photons, protons or heavier ions, diamond will minimize beam losses and efficiently conduct energy that is lost to the cooling systems. Diamond is increasingly used for output coupling, filtering, beamsplitting, beam detection, position monitoring and sample holding. Diamond is often brazed into flanges to withstand pressure differences and can be thin enough to minimize absorption of x-rays.

DIAMOND TARGETS

Due to its low Z and high density, diamond has found interest as a target material for high power, short pulse length lasers. Its high density leads to a high shock velocity, so that a high energy yield can be delivered to a sample though a reasonably thin diamond holder. Its low Z leads to low xray generation, minimizing noise in downstream analysis equipment. The carbon ion beams that result from this laser bombardment have potential uses in fusion power development, ion cancer therapy and material studies.

Due to its low Z and high density, diamond has found interest as a target material for high power, short pulse length lasers. Its high density leads to a high shock velocity, so that a high energy yield can be delivered to a sample though a reasonably thin diamond holder. Its low Z leads to low xray generation, minimizing noise in downstream analysis equipment. The carbon ion beams that result from this laser bombardment have potential uses in fusion power development, ion cancer therapy and material studies.